Case Study Overview

The subject exploration well suffered a blowout and was on fire, while drilling a 12 ¼” hole at a depth of 1704’. The well was flowing gas, believed to be from a charged shallow sand zone. The actual source of the gas was not confirmed, but it was later determined that there was a casing leak on a nearby well located on the same drilling pad. Cudd Well Control (CWC) was contacted to assist in the well control operations.

Situation Upon Arrival

An initial assessment was conducted and a well control plan was devised. The fire was coming mainly from the substructure and was rolling around the rig floor to about 40’ tall. The rig was severely damaged by the fire. The derrick had fallen and was lying parallel to the catwalk. The Kelly was intact under the derrick debris and the swivel was in the mud beneath the V-door. The heat from the fire prevented any unprotected approach closer than ±100’.

Intervention Strategy

Since the drill string and Kelly were intact, the planned approach to tackle the situation was to kill the well via pumping down the drillpipe. Capping was not considered as an option as only 40’ of conductor casing was set on the well. A well control team comprising of personnel from the operator, the drilling contractor and service companies was formed.

Operations

A local firefighting pump was located and water from a 500 gpm firefighting monitor was used to cool the adjacent well. Preparations to kill the blowing well were being made while frac tanks to store kill fluid and firefighting water were set on location. The portions of the rig that could be removed without the use of firefighting water were disassembled and moved off location.

Kill fluid was being mixed on the drilling rig in the field. The next hurdle in the operation was to gain access to the swivel buried under the debris to tie a pump line. This part of the intervention was more challenging as due to the lack of firefighting equipment this work had to be performed in hot conditions, under the cover of heat shields. This work was tedious as the heat from the fire only allowed short periods of work to be accomplished.

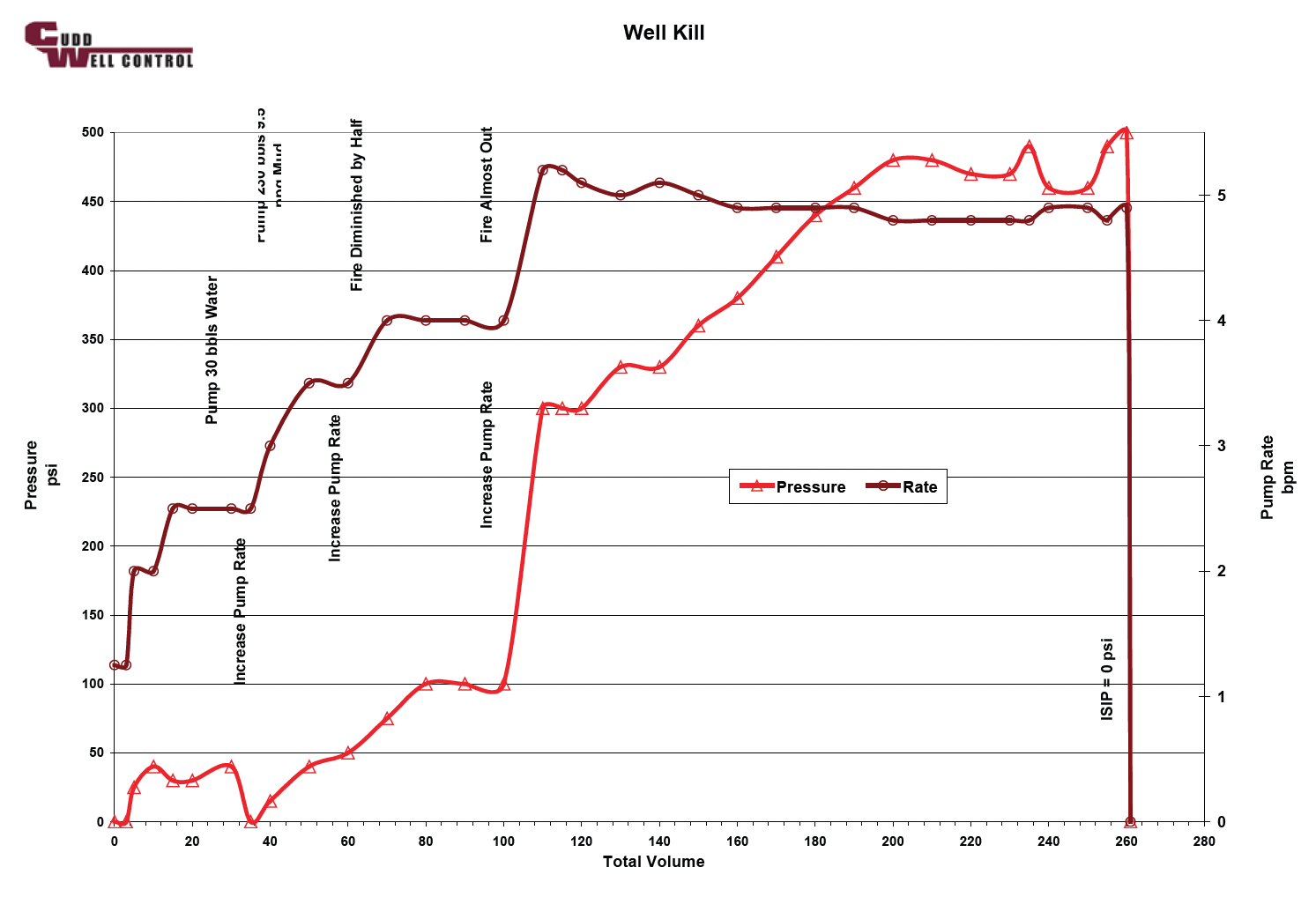

A cementing unit was rigged up and a pump line was installed on the swivel. After successfully testing the pump lines, kill operations were started. A 9.5 ppg water based mud was used for the kill operation. The mud was pumped at ±4-5 bpm. The well was successfully killed and the fire was put out after pumping ±260 bbl of mud. The pump pressure during the kill climbed throughout most of the operation but leveled off during the last 60 bbls. There was no evidence of fluid returns while pumping the kill. The well was static at the end of the job but the fluid level in the annulus could not be determined.

An additional pump operation was performed following the kill operation in an attempt to regain circulation. Partial returns were observed after LCM pills were pumped, but full circulation could not be established. The operator then decided to plug the well.

The derrick was cut away from the rig carrier and substructure and was removed. The debris on the rig floor was cleared giving access to the annulus. A 1” tubing was run into the annulus to a depth of ±350’ and the well was cemented.