FREEZE TECHNOLOGY

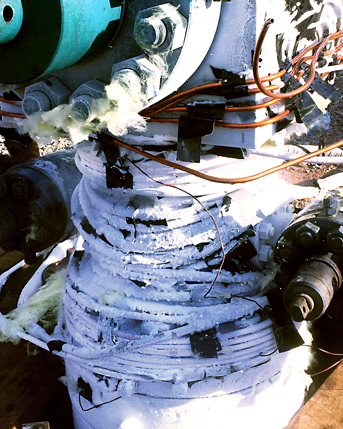

Freeze technology is a valuable service to generate a temporary barrier allowing repairs,

valve replacement, well head replacement, and pipe work on equipment. If a constant

supply of nitrogen is available, the freeze can be held until the job is complete. This

allows sufficient time to perform the work safely in a pressured or potentially

pressured system by creating a frozen “plug.”

Freeze technology can be performed on a wide range of pipe sizes up to approximately 48

in. This technology can also freeze through multiple strings of pipe. This is effective

through 5 annuli when the casing can be assessed. The freeze technology can translate

to valves, BOPs, production trees and pipelines as well. The technology uses either N2

or CO2 as the chilling agent to achieve sufficiently low temperatures to generate the

plug. The equipment requirements vary as to the type equipment or pipe being chilled

for the plug.

| Benefits |

|---|

| Cost efficiency and time saver |

| Reduces fluid costs / Requirements / Time utilizing fluids |

| Versatile Uses |

| Pipe sizes up to 48 in. |

| Valves |

| BOPs |

| Production trees |

| Versatile and light-weight equipment |

| Extended time, if needed |

Three major types of equipment are used:

Canister Freeze – for pipe or casing annuli

Coil Freeze – for irregular shapes such as a BOP component

Dry Ice – for production trees and extended time services

Other equipment includes the temperature monitoring systems, which are

specially designed for this work, thermal protective equipment, and possibly

thermal wraps / thermal blankets.

Freeze Applications

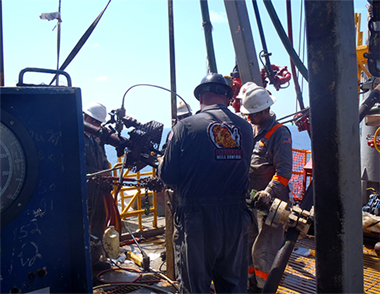

For more than 20 years, our cryogenic and dry ice freeze operations have provided access to critical

equipment, onshore and offshore, so that crews can perform maintenance or repairs while the wellbore remains

pressurized. Over the years, we have perfected the technique to increase the power of the temporary ice

plug, creating a highly functional field tool so that your team keeps cool under pressure.

Staging our unique approach to freeze operations allows for the removal and replacement of faulty equipment

with the peace of mind that the plug will hold for the length of time required to properly perform repairs

on BOPS, valves, production trees, and other non-cylindrical items.

We also perform cryogenic freeze operations on tubulars of all sizes, successfully plugging through multiple

casing and cement layers for a faster freeze that holds longer.

Safety

Proper PPE is required for the extreme temperature as well as minor safety training.

Only essential personnel are allowed within the designated working area. Planning

is required with the operator, third parties, and CUDD Well Control personnel.